The production and quality control system integrated with the ERP and process control systems

Control of the production covers technological wholes

- Storage of raw and packaging materials

- Weighing of raw materials

- Semi-finished products cookers

- Storage of semi-finished products produced

- Final products processing (filling the semi-finished products, packaging the final products)

- Warehouse of final products (on pallets)

- Laboratory QC processes (testing raw materials, packaging, semi-finished and final products)

Installed Manufacturing Execution System COMES involves the batch production scheduling and dispatching, control over the preparation of raw materials from the warehouse, material management using barcodes for labelling, control of the weighing process and its optimization in view of materials used, control over the cooking house using COMES Batch with a flexible recipe definition and producton records (EBR) and protocols (BP). Final production – filling & packaging lines are controlled with the COMES OEE applications supporting the effectiveness of the production while handing over the products through a direct communication to ERP Helios.

A significant part of the solution is the COMES for a control of quality, plans for sampling the materials, records on and evaluation of samples including a care about the calibration of instruments. An integral part of it are the electronic records on production along with protocols on batches and a support for releasing the batches.

Processing of the production order

Following steps summarize a sequence of processes of th production order:

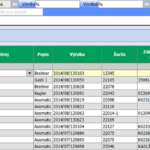

- Readout of data from Helios ERP about a receipt of raw materials and packaging materials.

- Generation and filling out of laboratory tests of newly received batches of raw and packaging materials.

- Sending the tests’ results from COMES to Helios.

- Preparation of released raw materials and packaging materials

- Import of actual production plan of semi-finished products from Helios into COMES.

- Scheduling of the production batches in the COMES Batch according to the production plan.

- Generation of a request for the weighing out of raw materials for all schedulled batches.

- Taking out requested raw materials from the storage.

- Weighing out required amount of raw materials and labelling them with a label with a barcode.

- Sending the weighed-out raw material to the cooking house of semi-finished products.

- Production of a semi-finished product according to COMES Batch production recipe.

- Distribution of semi-finished products into their packaging labelled with a label with a barcode.

- Sending information on produced semi-finished product packaging to Helios and storing them in the semi-finished products storage area.

- Import of actual plan for the final production from Helios to COMES.

- Creation of weekly shift-based plans and assignment of such individual plans to concrete filling & packaging lines in the COMES Modeller module.

- Starting the final production on shift-based plan within the concrete line. Recording of the consumption of materials and production of individual final products’ pallets. Correction of used-up input materials and produced pieces of a final product. Termination of the adjustment of the shift-based plan and sending confirmed data to ERP level.

- Laboratory testing of the final product by filling out the laboratory test forms of the finished product.

COMES server with modules

- COMES Logon

- COMES Historian

- COMES Modeller

- COMES Batch

Use of COMES standard application

- COMES control of batch production

- COMES control of weighing shop

- COMES quality control

- COMES OEE (Czech version)

- Electronically controlled production based on the ERP-COMES-PLC integration

- COMES Batch controls the workflow of cookers production operations

- COMES controls weighing raw materials processes using barcodes

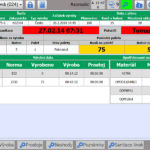

- The terminal for production and process control of the cooker technology

- The course of the electronic control of the batch in the cooker

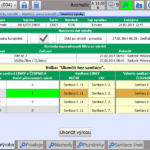

- The dispatching of production orders to the packaging lines

- COMES terminal with instructions for filling and packaging of batches

- COMES OEE manages the filling and packaging of batches

- The termination of the batch packaging process

- The termination of production and control of sanitation process

- Reference samples of manufactured cosmetics products