COMES applications can be used to measure consumption of energies which represents a significant part of the corporate costs. By using this application you will not only have the consumption of energies under control but you will also obtain a tool for minimizing it. Additionally you may relate the consumption to the production, series and batches so that you can better calculate real production costs.

COMES for monitoring the production and consumption of energies

Annotation

Some energy-demanding productions in particular, may make a system for measuring and evaluating the consumption of energies necessary for cost-effective production. Therefore the implemented COMES system, described in the application, apart from operational control and production monitoring, focusses on energy savings. Energy can well be measured with respect to a production process, so that the consumption is related to a particular production order. Managers may better control the production and optimize the energy costs, because, for example, even high energy consumption may be fine provided that appropriate amount of production is made.

Objectives of the solution

- Real-time monitoring of the energy consumption.

- Automated production data acquisition so as to save and minimize energy costs spent on production batches in real time

- Optimizing energy consumption with respect to the needs of the production

- Elimination of paper records and documentation

- Transferring the data to ERP system

- Provision of real-time information on corporate network computers and mobile devices.

Solution of the project

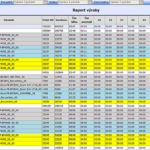

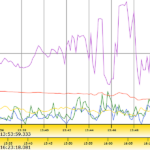

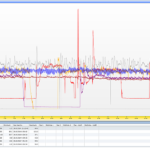

The application was configured using COMES Modeller module such that it contained most of the above functions. The format of the output reports was such as to meet the users‘ wishes who preferred an, rather unusual, at-first-sight display of data and the state of the production to a standard neat format of the display. COMES Historian module was used to collect and archive process data from the control systems and process it in the form of graphs (trends) and tables (alarms and reports).

COMES Architecture

Aplikace využívá systémovou architekturu COMES klient-server. Byla využita standardní IT strukturu podniku (viz. obrázek), existující IT server s virtualizací pro COMES, uživatelská PC, mobilní prostředky. Dodavatel řešení, firma COMPAS, jejíž druhou aktivitou je průmyslová automatizace, dodala kompletní řešení včetně návrhu měřicích prvků (elektroměry, čidla na průtoky a spotřeby energie aj.), takže klient získává garanci za celkovou funkčnost systému.

The application architecture is the client-server. A standard IT structure of the enterprise, an existing IT server virtualized for COMES, user PCs, mobile devices were all employed (see picture). The solution provider, the COMPAS company, supplied a complete solution including process automation and the instrumentation (electrometers, flow and energy consumption gauges …). So the client was provided with a warranty for an overall functionality of the system.

Visualization with statistics

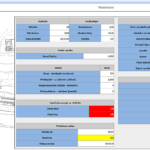

On the background of the plant’s layout the screen on the picture shows the actual production state of individual production workplaces and the information on the energy consumption related to the amount of products produced and production orders. Apart from the basic indicators it is possible to call up an overview screen containing more detailed information.

Benefits of the project for energy monitoring and production evaluation

Every customer appreciates a smooth project progress, meeting the deadlines and goals of the project including full warranty for the system functionality. An easy to implement COMES system thus provided the user with an integrated modern solution for the automation of the lines (revamping of which was ensured by COMPAS company too), as well as a powerful solution for effective production management, and technology capable of energy costs evaluation.

Thanks to the COMES system architecture the production information was made accessible to the Huhtamaki workers through a web browser virtually anywhere.

They got a powerful IT system helping them achieve excellent results of the plant within the production facilities installed.

- COMES andon – plant overview

- Daily reports of production lines

- COMES Historian trends of the energies consumption

- COMES Historian trends of the electric energy consumption

- The production line process tags in trends

- COMES Historian trends of the press air consumption