On decision-making, managers of all levels need credible information about actual state of the production and the time period passed. Should they have the information they succeed in improving the production. Independent of human factor the automated data acquisition and production monitoring (as opposed to manually acquired data) represent objective evaluation of the production effectiveness. A suitable tool for determining the real-time results of the production and analysis of the causes of unsatisfactory values, is the COMES OEE app. (czech version).

In practice, COMES OEE has been chosen by many users that value its built-in functions, modern architecture and speed of installation. Application can automatically monitor production data and evaluate it in the form of statistics.

Examples from practice

It has been interesting to see how wide a spectrum of objectives was monitored by the managers when using the COMES OEE (czech version).

Finding out about actual runtime of the technologies

A major food manufacturer has in several plants lots of technological equipment. Because of its supplying to retail chains that often change their requirements, the production incessantly struggled to keep the deadlines and scopes of production orders. Due to this, discussion surfaced between the production and management staff as to whether there were enough technological facilities, whether or not it was necessary to get some more, whether or not the maintenance did a good job in keeping the machines in operation. The goal of COMES OEE was to find out about and document the production reality. It was implemented in two stages. First the monitoring of operation of selected devices was installed (within days from the decision). Having brought the benefits, the monitoring was extended to 100 devices within three plants. It all resulted in determining the real utilization of devices and proposals for optimizing the production organization.

Use of working time

A major healthcare tools manufacturer works in 2-3 shifts. The management wanted to examine how the working time of the key machines that represented the bottleneck of production was being used. The production plan was met, but the management hoped for better utilization of the machines. Problems were identified mostly in the evening and night shifts when the management was not present in full. Having installed the COMES OEE it was shown, that the latter shifts had indeed some leeway and that the working time was not used to the full and the key machines might have produce even more products.

Production team awareness

An important factor, which COMES OEE contributes to a success in the process of improving the results, is the awareness of the whole production team including operators and workers. It has been proved beneficial to keep workers at the machines informed right through the terminal or the large screens – see picture, for them to see the results of their work. This awareness is the first self-acting factor of improving the production. Its efficiency may significantly be increased by making the production team be interested in the results.

Scrap production reduction

Automotive parts producer manufactures the parts by plastics injection and wanted to improve the uniformity of production process quality. The task of the quality monitoring system installation was, to instantly advise the maintenance staff of the repeated nonconformities in the products quality due to excessive mold wear or defect. Having installed the COMES system, the mold maintenance staff was being instantly informed of any nonconformity caused by the mold state, or by other reasons. Then the maintenance staff might immediately intervene (replace the mold) so as to keep the number of nonconforming pieces below specific tolerance and avoid loss of effectiveness.

COMES OEE helps you improve overall equipment effectiveness by processes of optimization:

Produce more products by:

- production team motivation, working time utilization

- reduction of downtimes – thanks to the identification and analysis of the real causes of the downtimes

- monitoring cycle – recording achieved values, notifying of the production cycles being exceeded

- monitoring the throughput of the equipment – e.g. utilization of individual devices in the line, and evaluation of causes of such a case.

By improving the conforming vs nonconforming products ratio, recording and evaluating the causes of:

- Operator errors,

- Adjustment times, responding to faults (rectification),

- technological production problems, etc.

COMES system

COMES OEE can be installed independently of the other parts of the COMES MES system, which contains other useful production IT functions.

- The effectiveness measurement of the sausage packaging lines

- The COMES terminal for the food industry

- The touch HMI for an operator data input

- Monthly progress of the OEE on machine exceeding the labeled performance

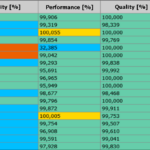

- Non-conforming products by orders for the selected machine

- COMES protocol with OEE ranges highlighted by colours