Batch production Quality Control of COMES includes:

COMES functions:

- Creating quality related material specification

- Laboratory evaluation of raw materials, intermediate products and products

- Creating reports and protocols

- Management of calibration of instruments, watching their expiration date

Creating quality related material specification

For each material (raw material, packaging, semi-finished and finished product) the quality assurance worker issues unambiguous specification of parameters defining properties of sensory, or of physicochemical and microbiological origin to be tested, together with the limits of such properties, conditions and procedures of tests. Individual tests are then generated in compliance with these quality specifications.

Laboratory evaluation of raw materials

Based on the receipt of raw materials and packaging materials in EPR system the MES level generates laboratory tests. For each newly received batch, one laboratory test, according to the quality specification of the particular material, is generated. Within the test, all received handling units of a specific material batch are shown, while it is possible to set the results of the test and expiration for each particular handling unit separately. It is therefore possible for some packaging to be released while others may be quarantined.

In case of using certificates of material suppliers, it is possible to scan the certificates and add them to the electronic documentation.

Laboratory evaluation of intermediate products

An example of a function for the production of semi-finished product

Having started the production of the semi-finished product a relevant laboratory test of such a product is created. In case of semi-finished products, tests of individual properties are carried out and then recorded twice – first the test sample is taken before the decanting and then again after the decanting of the semi-finished product. Within the test, all produced handling units of a particular batch of such semi-finished product, are created and it is possible to set the results of the test and expiration period for each particular handling unit separately.

Laboratory test of products

Example of a function

Having started the adjustment of a final product, a relevant laboratory test of such a product is created.

Within the test, the number of produced and released products, their expiration date and results of their testing, are stated.

Records and Protocols

Examples:

Records on the laboratory tests of materials

For each material in the test (raw material, packaging, semi-finished and finished product) it is possible to display a printable protocol containing all information entered during tests including the information on the result of the tests.

Protocols on weighing out material of a batch

For each semi-finished product production batch a protocol, summarizing the course of the weighing-out of all raw materials of the batch, is created. The protocol contains all important information stated also on the packaging, into which the raw materials were being supplied. The information includes: raw material identification, the amount of raw material in the package, packaging sequence number, total number of packages into which the material was supplied, identification of the operator who carried out the weighing, time spent on the weighing of the packaging, scale used, etc.

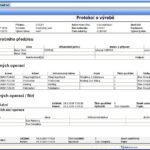

The electronic record and protocol of the production (EBR) and batch protocol (BP)

About each production batch a standardized electronic production record is being created during its production. This record contains detailed information about the production process as it happened during the batch control.

Out of the record a protocol on the BP batch production is created. The structure of the protocol follows the prescription of the product and contains individual operations that are further split into individual production steps. Part of this protocol are graphs of trends of fundamental quantities and alarms occurred during the production as received from the control systems.

Records on cleaning (CIP) and sterilization (SIP)

The pieces of equipment used in production are cleaned according to exact prescribed procedures. The procedure of the boilers cleaning is created in COMES system. Each CIP/SIP process is accompanied by the EBR record and the BP protocol of similar structure as the one from the batch production itself.

Supervision the Calibration of Measuring Instruments

COMES allows you to keep records on calibration of instruments. Should the instrument be used in the tests COMES checks the validity of calibration and, in case of its expiry, the instrument is no longer offered for the test.

Benefits of COMES for Batch Production Quality Control

COMES system serves to specify scheduled tests of the batch production quality. It enables electronic communication of the test results within production team, utilization of results for the next production steps, protocols and quality statistics.

It further allows you to create production documentation in the electronic form including electronic signatures and monitoring of production costs, it allows the data to be transferred to economic/accounting IT systems. At the same time, COMES supports the maintenance team and controls service activities for technologies and their parts.

The users appreciate the state of art solution, the opportunity to be one step ahead of their competitors, a rapid return on investment and the support of the COMES manufacturer strong team.

- COMES LAB supports quality management

- COMES evaluates test results of materials and controls its status

- Elektronically recorded batch data in the protocol